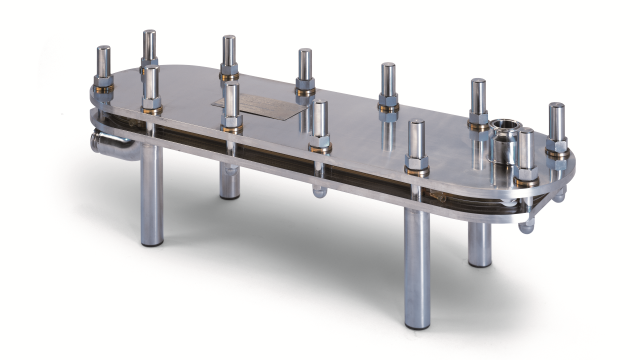

LabStak M39 L/H

The Alfa Laval LabStak® M39L/H is specially developed for ultrafiltration and microfiltration of highly viscous products and fermentation broths. The unit is ideal for a wide range of industries that include biotechnology, pharmaceuticals, food and beverages. To meet the demands experienced here, the Alfa Laval LabStak® M39L/H is designed for optimized flow dynamics, low energy consumption and pressure operation. Optional plate sets are available for different liquid viscosities

Handy and flexible

The Alfa Laval LabStak® M39L/H is designed to provide quick and reliable process evaluations in laboratories or other test facilities, while keeping equipment and set-up costs to a minimum. The unit is a popular choice for up-scaling, membrane testing, quality assurance, process development and small-scale production.

The flexible Alfa Laval LabStak® M39L/H consists of a full-size plate-and-frame cross flow membrane filtration module of the type Alfa Laval Module M39L/H. This module is the same as those found in full-scale membrane filtration systems from Alfa Laval, designed with modules of the type M39L/H. As such the Alfa Laval LabStak® M39L/H utilizes support plates of the same size and it can be fitted with the whole range of flat sheet membranes for ultrafiltration and microfiltration, also available from Alfa Laval.

Option

For the Alfa Laval LabStak® M39L/H we offer plate sets with different channel heights to optimize flow and pressure:

- M39L plate set

Low channel, for low and medium viscosity liquids - M39H plate set

High channel, for high viscosity liquids

Alfa Laval LabUnit M39L/H

The Alfa Laval LabUnit M39L/H is a fully integrated system comprising an Alfa Laval LabStak® L/H unit complete with necessary pump, valve, heat exchanger and instrumentation.

The Alfa Laval LabUnit M39L/H is a fully integrated system comprising an Alfa Laval LabStak® L/H unit complete with necessary pump, valve, heat exchanger and instrumentation.

Benefits

- flexible membrane area between 0.2 m² and 1.0 m²

- simultaneous testing of up to five different membrane types

- easy exchange of membranes

- high operating temperature (up to 80°C)

- can be coupled to the by-pass stream of an industrial plant

- different channel height options to optimize flow and pressure

- low internal volume

- flexible system design

- flow pattern similar to that of larger systems

- all components in compliance with FDA regulations, allowing use within food and pharmaceutical processing applications

运行原理

阿法拉伐的板框式模块设计有横跨膜表面的开放通道。进料流/滞留物流过这些开放通道。

膜本身由带有许多槽的中空板支撑,这些槽可收集渗透液,并通过渗透液收集管从模块中排出。

v板框式模块在锁环或锁条的帮助下使用膜本身将进料/滞留物密封,防止其混入渗透通道。这也避免了板组(plate stack)本身的任何泄漏风险。