Plant-based protein and vegetable processing systems

Rising demand for alternative proteins calls for reliable wet fractionation processes that boost purity, nutritional value and yield, of protein isolates while reducing consumption of energy and water. Sustainable plant-based protein processing systems from Alfa Laval deliver reliable performance and reduce environmental impact while ensuring protein stability, appearance, texture, taste and nutritional value.

Boost the quality and yield of plant-based protein food and drink products

- Complete utilization of raw material

- High hygiene standards

- High purity, high quality and high yield

- Low energy and water consumption

- Minimized freshwater intake and environmental impact

Turning oilseed crops, such as soybean, rapeseed and sunflower seed, and starch crops, including pea, chickpea, fava bean and mung bean, into high-quality proteins for food and feed requires know-how.

Take advantage of comprehensive, energy-efficient solutions for plant-based protein processing systems from Alfa Laval. From oilseed and starch protein extraction, isolation and purification through to process water recovery, and wastewater treatment, you will discover a sound and sustainable approach to meeting the growing global demand for meat substitutes.

Food and beverage manufacturers turn to Alfa Laval for expertise, service and support to develop, test and optimize vegetable protein processing systems to ensure fast scale-up from pilot- to commercial-scale production.

Broad portfolio for processing edible proteins

With a focus on the wet fractionation process, Alfa Laval has a broad portfolio of systems for processing plant-based proteins. Whether you need reliable standalone equipment to integrate into your existing lines or complete customized production lines, Alfa Laval delivers equipment and systems for oilseed and starch protein extraction, isolation and concentration, including:

- Slurry preparation

- Protein extraction, separation and purification

- Pasteurization systems

- Fibre and starch separation and purification

- By-product recovery

- Wastewater treatment and water recovery

Alfa Laval oilseed processing systems

-

Solubilization. The first step is mixing a lye solution together with oilseed white flakes to make the protein soluable by increasing the pH value of the resulting slurry.

-

Protein extraction. Next, the slurry is processed in an extraction decanter, to separate the solubilized protein from the solids (fibre).

-

Second extraction. The solid cake is then washed with water to extract additional protein not released during the initial extraction. A second extraction decanter then processes the resulting slurry, separating the solids (fibre) from the liquid. The solids from the second decanter can be then sent to a dryer or to a biogas plant.

-

Protein precipitation. The liquid collected from both extraction steps is processed to lower its pH value to the isoelectric point of the protein, causing the protein to precipitate out of the liquid. The precipitated protein slurry then enters a protein decanter, which separates the protein precipitate from the liquid.

-

Protein washing. In the last step, the protein is washed with water to increase the protein purity. This results in a protein product with higher purity and better organoleptic properties. However, this step may be omitted if the goal is not to produce a high-purity protein product.

Alfa Laval starch crop processing systems

-

Solubilization. The first step is mixing a lye solution together with flour to make the protein soluble by increasing the pH value of the resulting slurry.

-

Protein extraction. Next, the slurry is processed in an extraction decanter to remove the solubilized protein from the solids, which consist of starch and fibres.

-

Fibre removal. Rotational fibre screens filter the solids, removing fibre from the starch. Before drying, wet fibre can be sent to another decanter for further dewatering before drying, or can be used in biogas or bioethanol production.

-

Concentration and starch washing. Diluted starch milk is then concentrated and transferred to a hydrocyclone starch washing system. Washing refines the starch milk, which can then be dried into starch powder or used for bioethanol production or in syrup production.

-

Protein precipitation. Liquid collected from the extraction step (2) is processed to lower its pH value to the isoelectric point of the protein, causing the protein to precipitate out of the liquid. The precipitated protein slurry then enters a protein decanter, which separates the protein precipitate from the liquid.

-

Protein washing. In the last step, the protein is washed with water to increase the protein purity. This results in a protein product with higher purity and better organoleptic properties. However, this step may be omitted if the goal is not to produce a high-purity protein product.

Optimizing plant-based protein processing systems

Take advantage of Alfa Laval’s expertise in designing plants for fractionation of agricultural products. Test your feedstocks under actual operating conditions at the Alfa Laval Food & Water Test Centre in Denmark, to determine the optimal system for your processing requirements.

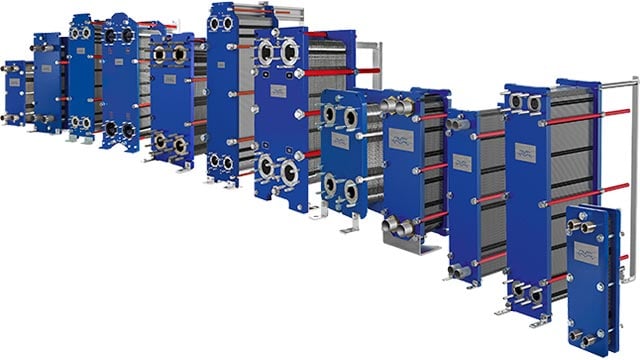

Core equipment in our plant-based protein processing and vegetable processing systems

服务

食品系统服务

阿法拉伐食品系统服务通过最大程度地提高工艺性能来帮助提升食品系统的性能。 这使您能够:

- 不断改善您的运营以保持竞争优势

- 专注于正常运行时间、优化和可用性

- 在您的食品系统的整个生命周期内最大程度地提高投资回报率