技术信息——焊接式螺旋式换热器

在螺旋式换热器的设计与制造领域,市场上没有哪家供应商能比阿法拉伐拥有更丰富的经验。凭借超过五十年的专业积累,阿法拉伐已经成为解决复杂工艺问题的终极解决方案。继续阅读,了解支撑这一成就的核心技术、可选型号以及独特创新。

螺旋式换热器的工作原理

螺旋式换热器运作方式

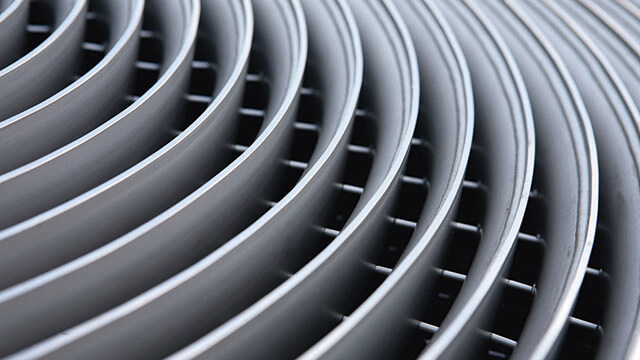

阿法拉伐螺旋式换热器式圆形装置,内部包含两个同心螺旋流道,每个流道对应一种流体。不同流体反向流动:一种流体从装置中心进入并向周边流动,另一种流体则从周边进入并向中心流动。流动呈曲线形且具有均匀的横截面,不会发生流体的混合。

产品通道通常一侧开放,另一侧封闭。加热/冷却介质通道有时可能两侧均封闭,具体取决于加热/冷却介质的清洁度。每个通道在换热器中心和周边各有一个连接点。

螺旋式换热器设计

单通道几何结构还会产生一种我们称之为SelfClean™设计的清洗效果。如果热交换通道内发生结垢,该部分通道的截面积会减小。然而,由于整个流体仍需通过该通道,流速会增加,由此产生的流体压力会将形成的沉积物冲掉。

将此设计与壳管式换热器进行比较,后者的流体并行进入不同管束。当管束开始结垢时,压降增加,迫使流体流向新的路径,导致管束的结垢和堵塞会非常迅速的发生。而使用阿法拉伐螺旋管时,结垢和堵塞几乎能够被完全消除。

我们的焊接螺旋产品系列

SpiralPro 用于液体至液体的任务

SpiralPro 用于蒸汽加热器任务

还提供经过优化、可用来蒸汽加热高度污染的液体的 SpiralPro 型号换热器。 与所有 SpiralPro 装置一样,这些装置完全可以通过液压喷头快速方便地清洁。

逆流流动还确保了非常小的温差,以实现最大的热效率。

应用

- 需要蒸汽加热的含有固体或纤维、液体、浆液和污泥的污垢液体以及其他具有挑战性的流体。

SpiralCond 用于真空冷凝和蒸发任务

阿法拉伐焊接螺旋式换热器的独特功能

卓越的清洁效果与持久的性能表现

螺旋单元中的每个回路均由单一流动通道组成。这种连续弯曲的单通道几何结构可以产生高湍流,从而一开始就最大限度减少结垢。如果结垢开始发生,局部流速会增加,因为流体仍会通过。这会产生一种清洗效应,将形成的沉积物冲掉。

该设计的一个额外优势在于,它消除了死角和热量滞留的风险,从而实现高效的热传递。

可靠的自动化封装

阿法拉伐螺旋式换热器的制造过程采用了自动化的通道边缘弯曲工艺。随后,通过冷金属转移自动焊接机完成最终的封口焊接。

这种名为RollWeld的技术所产生的综合效果是通道封闭质量的一致性。这反过来对通道焊缝的强度和耐腐蚀性至关重要,从而确保整个单元的可靠性。

专为高压工况设计的定制解决方案

对于那些工艺流程对设计压力和压差要求高于传统螺旋式换热器所能提供的客户,阿法拉伐具备能力能力,可以完全定制化计划一套独特的解决方案,以满足特定需求。

我们采用多种设计特征打造 HighP螺旋式换热器,包括双密封垫系统、自支撑内部盘管以及带螺栓盖的特殊壳体和外壳。我们的资深工程师将会全程参与设计过程,确保您获得针对特定挑战的理想换热器解决方案。

HEXpert 选型工具

快速找到适用于严苛工艺应用的理想焊接板式换热器。填写您的工艺需求信息,5分钟内即可获得高效热解决方案的定制化推荐。