Advanced cloth media filtration for tertiary wastewater treatment keeps the Credit River clean

The Region of Peel chose the Alfa Laval ASH Iso-Disc® cloth media filter for tertiary filtration when they expanded and upgraded the municipal Inglewood Wastewater Treatment Plant in Ontario, Canada. The Iso-Disc® filter technology met all of their requirements: high-quality effluent, a small footprint, easy integration into the existing plant, and low maintenance.

DATE 2025-07-12

The Village of Inglewood, located on the Credit River north of Mississauga in Ontario, Canada, was growing due to residential development. The resulting increase in wastewater posed a potential threat to the Credit River—a waterway known for Chinook salmon angling, canoeing, kayaking, conservation areas, and a provincial park.

Challenges with reliability and risk of non-compliance

The local Inglewood Wastewater Treatment Plant, which has a capacity of 243 m3/day, was also facing new stricter guidelines for effluent discharge levels from the Ministry of the Environment.

At the same time, the plant’s traditional sand filters, a commonly used technology for tertiary filtration in Ontario, had reached the end of their life time. The filters could no longer provide adequate reliability or capacity and had become a bottleneck for plant expansion. The risk of discharging unfiltered effluent into the watershed during peak flow conditions was a significant concern.

The old underground sequencing batch reactor (SBR) for secondary biological treatment, based on activated sludge, had also aged and no longer met modern standards.

The Region of Peel therefore decided to upgrade the Inglewood plant to improve the reliability of the treatment system. This included installing 100% redundant equipment to ensure compliance with Ministry guidelines during peak flow conditions.

Compact wastewater filtration system

The first priority was to urgently resolve tertiary filtration bottlenecks to ensure compliance with effluent discharge limits at all times. However, sand filters require significant space, and accommodating additional equipment would come at a high premium. Replacing the sand in the old filters—housed in a small building—would also be too costly.

The Region of Peel therefore looked into an alternative and more compact filtration solution that would also improve overall process reliability and flexibility, and provide equipment redundancy. Ease of maintenance was crucial given the limited space.

The right solution: ASH Iso-Disc® cloth media filter

With a proven track record in the region, Alfa Laval Canada was a natural choice for the project. Since 2000, the company had supplied 14 wastewater decanter centrifuges and six Aldrum rotary drum thickeners to various wastewater treatment plants across Peel, and had previously collaborated with the engineering consultant on similar upgrades.

The ASH Iso-Disc® Cloth Media Filter from Alfa Laval emerged as the optimal solution to the region's challenges, thanks to its compact design, low footprint-to-flow ratio, and ease of operation and maintenance. Additionally, the cloth media polishing filter provided the fine particle filtration necessary to meet strict effluent discharge requirements.

As a result, two ASH Iso-Disc® filters were ordered. The first was installed at the existing Inglewood plant in early 2015.

As part of the plant's ongoing upgrades and the planned replacement of the aging SBR with a more flexible, modern system, a new building will be constructed to house both the second ASH Iso-Disc® filter and, eventually the first filter as well. It is therefore an advantage that the equipment can easily be relocated once the new building is ready.

Alfa Laval’s local team worked closely with Inglewood’s plant engineers and the engineering firm CIMA Canada to select the solution that would best meet the regulatory requirements and provide the desired process flexibility. During installation, Alfa Laval’s senior service engineer worked alongside the supplier of the locally produced filtration system controls to integrate them with the plant’s overall control system.

Meeting all requirements

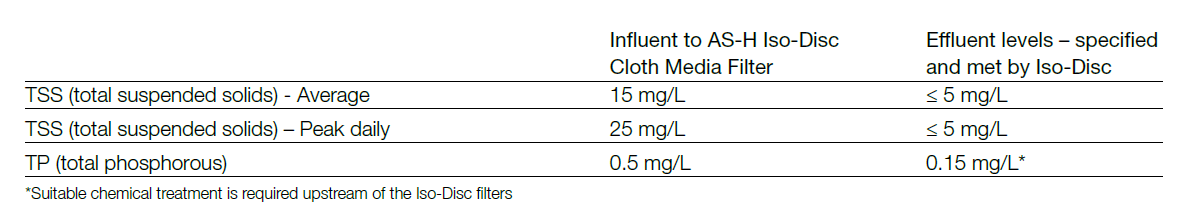

The first year of operation with the Iso-Disc filtration technology at the Inglewood Wastewater Treatment Plant confirmed that the system meets all requirements: an average daily flow of 243 m³/day, peak daily flow of 729 m³/day, and peak hourly flow of 1,118 m³/day.

The Iso-Disc® filters are running well operationally and compliance wise, and they have also reduced our maintenance significantly,” said a representative from the Region of Peel’s Wastewater Plant Operations team.

突出技术

The gravity-driven continuous Alfa Laval ASH Iso-Disc® Cloth Media filter with outside-in filtration removes residual solids e.g. <5 mg/l suspended solids and <10 mg/l BOD from wastewater to a high final effluent quality (down to 5-10 µm) suitable for reuse.

Reduce your environmental footprint with Alfa Laval's complete spectrum

Alfa Laval helps reduce the environmental footprint from water and waste streams, by maximizing reuse of water, by turning waste to value, and by minimizing energy consumption and waste. We offer a complete spectrum of equipment for wastewater treatment, filtration and sludge treatment that helps produce clean effluent for discharge or water reuse, recover heat and reduce the amount of sludge for disposal.