选矿

Alfa Laval’s range of equipment and proven expertise help optimize key processes in coal beneficiation and add further security to the storage of mine waste. With our solid-bowl decanter centrifuges installed, you can look forward to recovering and re-using large quantities of process water, which will help cut lifecycle cost, minimize environmental impact, save space and boost capacity as well.

Robust technology for coal tailings dewatering

- Excellent output (solids dryness) even in tough conditions

- Removes need for tailings dams

- Reduces footprint as well as capital and maintenance costs

- Contained process resulting in good and safe working conditions

- Full support from our global sales & service team, even in remote locations

Tackling tailings safely and sustainably

Alfa Laval decanter centrifuges are a proven, efficient solution for large-scale dewatering of tailings and removing the finest particles that conventional solids control equipment is unable to deal with. They offer a cost effective, sustainable and, above all, safe solution to manage tailings, acting as a complement to traditional separation systems such as thickeners, sedimentation basins and filters or replacing old systems altogether.

技术工作原理

阿法拉伐P2和P3卧螺离心机专门用于将矿浆和尾矿分离成固相和液相,分离在配备螺旋输送机的水平圆柱形转筒内进行,给矿浆通过固定的进料管进入转鼓,然后在给矿区平稳加速。高达 3,500 G 的离心力将固体颗粒从液体中分离出来,固体堆积在转鼓的内表面。

输送机的旋转方向与料碗相同,但速度不同,这给固体颗粒带来了轴向推力,传送带将这些颗粒向碗的锥形端输送。固体颗粒通过固体排放口离开贮料碗进入机壳,而澄清液体则流过可调节的板坝或动力管进入机壳离开贮料碗。

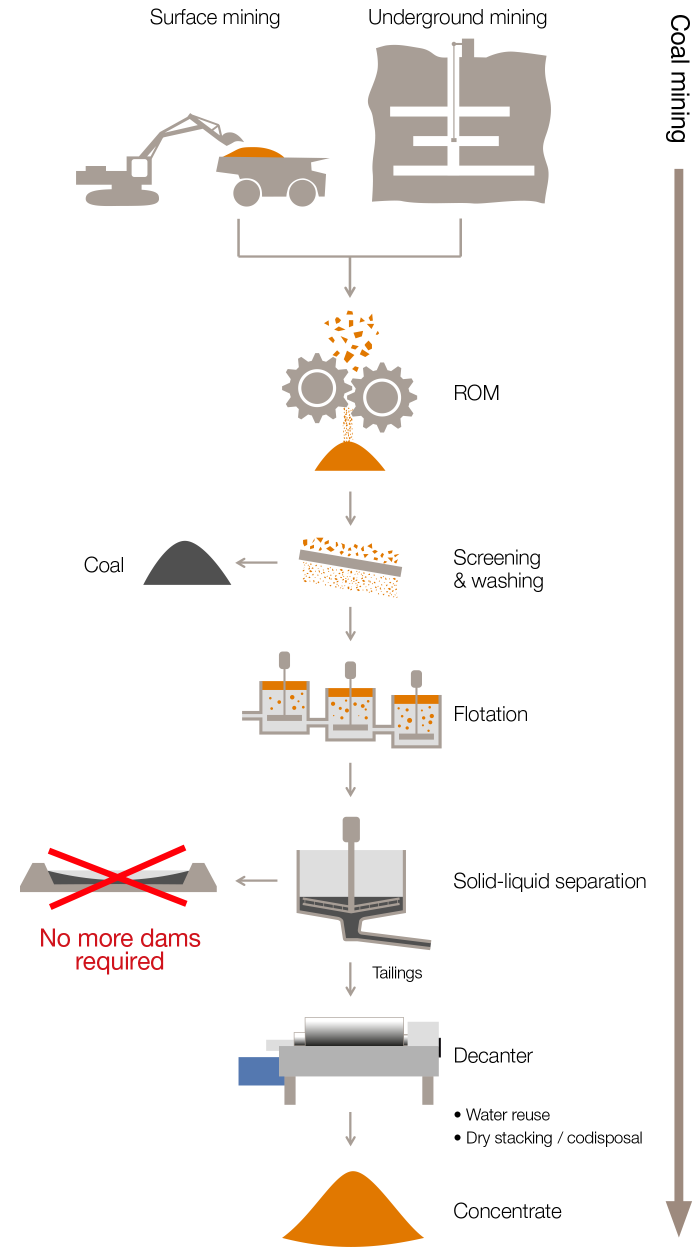

Opportunities throughout your process

Explore the mining flowchart and discover how an Alfa Laval decanter centrifuge can help streamline your operations in various process areas.

Tailing dewatering - Breaking new ground in mining and minerals

Alfa Laval decanters revolutionize coal mine tailings management strategy.

The Rix’s Creek coal mining operation, part of the Bloomfield Group, set out to improve its onsite coal tailings management as part of its sustainability strategy to reduce water and energy consumption and minimize the surface footprint of waste handling processes.

After evaluating various technologies, Rix’s Creek engineers installed an Alfa Laval decanter centrifuge to dry coal tailings.

The result? Savings in capital expenditures as well as, about 90% recovery and re-use of the process water.

Learn more

Read more about the efficiency, practicality and technical details of the Alfa Laval range of solid-bowl decanter centrifuges for the coal mining industry by downloading the brochure.

尾矿管理

阿法拉伐卧螺离心机可应对尾矿脱水的挑战。阿法拉伐卧螺离心机为尾矿管理提供了经济、可持续、安全的解决方案。下载宣传册,详细了解我们更清洁、更高效、更安全的固液分离系统。

Make sustainable development happen!

If you are looking for ways to increase the efficiency of your coal tailings management and make a meaningful contribution to the global sustainable development goals, contact Alfa Laval today to learn more about our proven and cost efficient solutions.