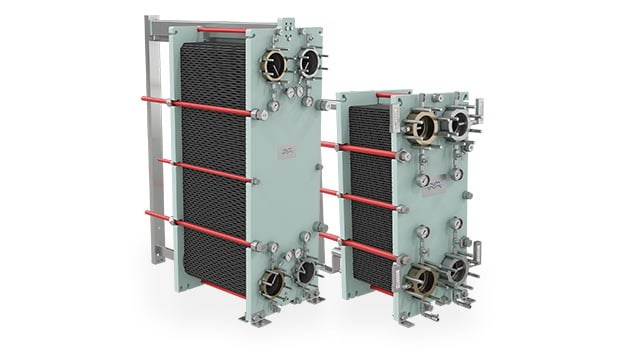

Marine gasketed plate heat exchangers

Alfa Laval has been developing heat transfer technology for more than 80 years and has been active in the marine industry for over a century. Based on that vast wealth of experience, our engineers have designed gasketed plate heat exchangers that set entirely new standards – not only for reliability, but also for thermal performance and ease of service.

The marine industry’s most modern line of plate heat exchangers

- Superior reliability and energy efficiency

- Small size and footprint (CompactFrame™ design)

- Minimal fouling (CurveFlow™ plate distribution area)

- Easy installation and service (five-point alignment system)

- Optimized global supply chain and production for smallest environmental footprint

Suitable for any vessel, Alfa Laval gasketed plate heat exchangers excel in applications from general heating and cooling to heat recovery, condensation and evaporation. With their innovative features, they take reliability to an all-new level and save crews time and effort during maintenance. Above all, their design minimizes fouling and maximizes heat transfer capabilities, which ensures the highest possible energy efficiency.

关键产品

Gasketed plate heat exchangers for your vessel

Compact, reliable and energy-efficient, Alfa Laval gasketed plate heat exchangers are also safe and simple for crews to maintain. Our flexible marine line provides the right match for your needs today – with the possibility to adjust capacities later.

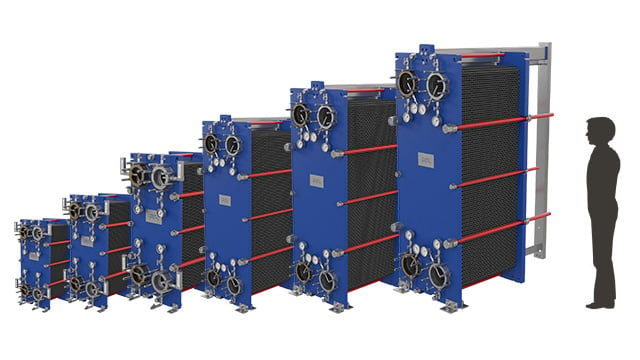

| T6 DN 60 |

T10 DN 100 |

T15 DN 150 |

T21 DN 200 |

T25 DN 250 |

T35 DN 350 |

|

|---|---|---|---|---|---|---|

| H (mm) | 890 | 1054 | 1833/1781 | 2082 | 2761 | 2875 |

| W (mm) | 320 | 470 | 610/650 | 755 | 913 | 1174 |

| Max flow rate (m3/h) | 60 | 160 | 370 | 650 | 1000 | 1970 |

| Capacity (kW) – water duty with LMTD 6 | 800 | 3 000 | 9 000 | 18 000 | 28 000 | 35 000 |

工作原理

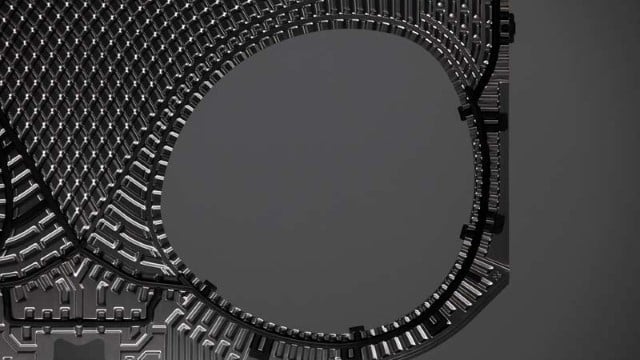

垫片式板式换热器的传热区域由一系列波纹板组成,这些波纹板组装在框架和压紧板之间以保持压力。 垫片充当板之间的密封。 流体通常逆流通过热交换器。 这提供了最有效的换热性能,并实现了小温差换热,即出口工艺介质和进入服务介质之间的温差。

阿法拉伐液-液垫片板式换热器

Features that make the difference

The Industrial line is equipped with features that turn this high-performance family into efficient and reliable workhorses that are easy to service and maintain over the whole product lifecycle.

For efficiency

By improving the efficiency of your heat exchanger, you can maximize production and minimize energy consumption to reduce your power bill and improve your environmental footprint.

See product animations below or get more information and listen to our technical experts.

CurveFlow™

CurveFlow™

弧形导流

改善介质流动

最小化结垢风险

OmegaPort™

OmegaPort™

流线通孔

提升介质流量

降低压降

FlexFlow™

FlexFlow™

板片设计

提高换热效率

优化压降

For reliability

We are always looking to increase the reliability of every aspect of our gasketed plate heat exchangers.

We focus on durable designs based on robust materials and safe manufacturing processes.

See product animations below or get more information and listen to our technical experts.

PowerArc™

PowerArc™

弧形强化

防止板伸长,改善板刚性

五点校准

五点校准

板材校准完美,机械性能可靠

SteerLock™

SteerLock™

板片导锁

确保可靠的板片定位和简便的维修

For serviceability

The simple opening and closing of the plate-and-frame design with gaskets enables hassle-free inspection and service. It also enables you to easily adapt the unit to new process conditions.

See product animations below or get more information and listen to our technical experts.

ClipGrip™

ClipGrip™

垫片固定牢靠,防止板组卷曲

丁字滚梁设计

丁字滚梁设计

尽量降低装置高度,开关方便,防止卡堵

轴承套

轴承套

安装拆卸安全方便,无需专用工具,最大限度减少轴承架损坏

减阻轴承

减阻轴承

确保易于打开的设备,以实现更顺畅,更有效的维护

服务

如何找到我们?

Documents

Downloads

Instructions and manuals

Product brochures

Heating and cooling in an engine room

On a ship, there are many types of machinery with a cooling demand. When the heat energy cannot be recovered or utilized, the total costs of transferring it away from the machinery should be kept to a minimum. Alfa Laval can ensure a cost-effective central cooling system through our portfolio of innovative plate heat exchangers. Our gasketed plate heat exchangers have unique features that reduce the running costs for engine room cooling – and contribute to sustainability.

Are you on a quest to save energy?

Alfa Laval is setting the standard for thermal efficiency of plate heat exchangers. Bringing together innovative features improving energy efficiency and minimizing downtime we can accelerate the transition to more sustainable solutions and reach net-zero by 2050.

Alfa Laval technology powers sustainable operations on Maersk’s pioneering methanol-fuelled container vessel

In a world where sustainability is increasingly important, A.P. Moller-Maersk has set sail with the world’s first methanol fuelled container vessel. Equipped with Alfa Laval’s solutions for methanol as fuel, this vessel shows how innovative solutions and equipment can help shipping companies adapt to the evolving energy landscape and environmental regulations.

需要新标准

介绍世界上最现代化的垫片板式换热器。 了解我们的下一代垫片式板式换热器系列将如何为您带来更高的效率、可靠性和可维护性。